1) In the gas PE pipeline operation handover, there are 5 conformity checks on the tracer line.

① Firstly, whether the signal pick-up point is available and installed correctly.

② Secondly, detection signal can be loaded to the tracer wire. Too many faults in the middle, serious leakage, no detection wells in the middle.

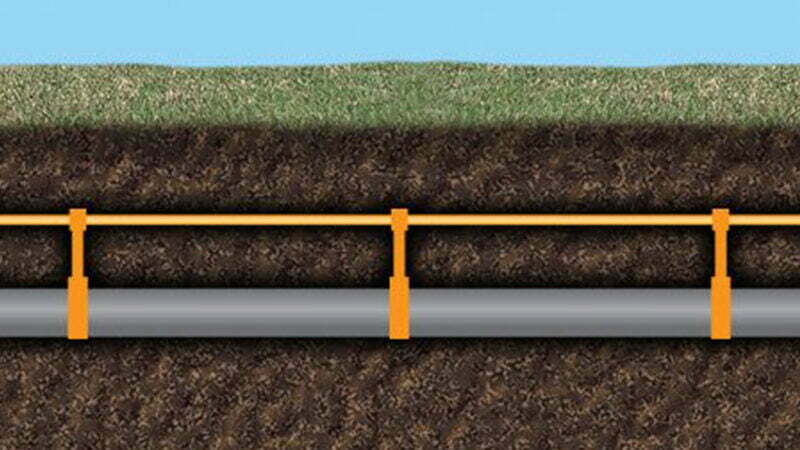

③ Thirdly, installed tracer line, the beginning end of the end cut off the suspension. No contact with the earth. The middle valve well tracer line can not fix processing.

④ Next and not the last, the tracer wire diameter is too small to meet the requirements of detection signal transmission. And construction excavation or natural stress damage will break it easily.

⑤ Lastly, bury PE pipeline surface marker by the impression of installation memory, with insufficient density and large deviation.

2) The detection signal cannot ensure continuous smooth flow, mainly due to five reasons.

① The conductor in the tracer wire can not connect well, causing a break.

② Tracer wire did not do insulation and waterproof treatment, resulting in signal short circuit.

③ Metal wire conductive area is not enough, resulting in large signal transmission resistance and signal attenuation.

④ The tracer wire itself is not qualified, the conductor occurs broken discontinuity.

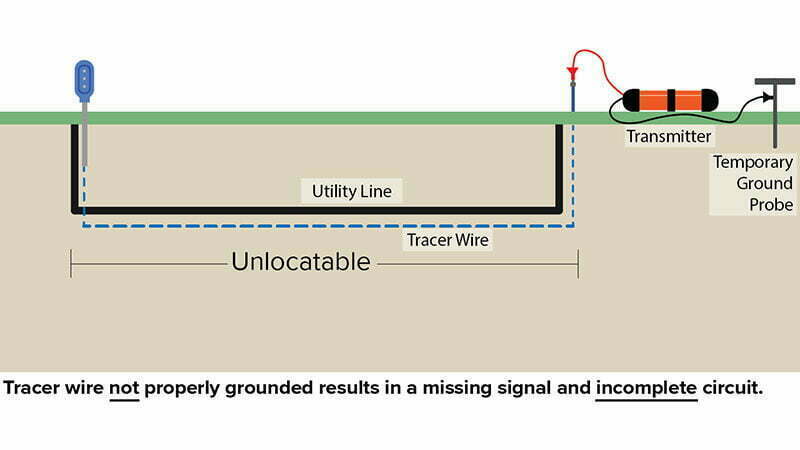

⑤ Tracer wire first and end do not connect and treat grounding, can not find the head.

3) No exposed detection signal source.

PE pipeline tracer wire without signal contact design. Not installed in accordance with the contact design. Many construction units in the tracer line installation, the tracer line joints directly buried under the surface, or the tracer line joints directly wrapped in the pipeline or equipment. In a very short period of time, the tracer line joints will not be able to find. Finally, it will result in the loss of the entire tracer line.

4) Area is too small, not strong enough.

Incorrect choice of metal wire cross-sectional area.

In short, the choice of tracer wire before to use. Different detectors have different detection principles and methods, the need to choose a targeted tracer wire.

The choice of metal conductor cross-sectional area needs to be based on the signal strength of the detector signal generator, the design of the pipeline required to detect the distance to choose the type of metal conductor and the cross-sectional area of the wire.

In general, 2.5mm² CCS-core wire can be detected at one time distance of 500 ~ 1000m.

To sum up, direct method will be farther, and construction rarely appear to pull off the phenomenon.