1.Development and Use

Horizontal directional drilling technology first appeared in the 1970s as a combination of traditional road perforation and oilfield directional drilling technology, which has become a popular construction method for transporting oil, natural gas, petrochemical products, water, sewage and other materials and for construction of various types of pipelines for electric power and fiber optic cables.

It is not only applied to the crossing of rivers and waterways, but also widely used in highways, railroads, airports, coasts, islands, and dense areas with dense buildings and pipelines.

2.Technical limitations

Directional drilling techniques were first applied to alluvial crossings along the U.S. coast, and are now able to begin crossing in complex geological conditions such as coarse sand, cobble, moraine and rocky areas.

The longest crossing has been 6,000 feet with an 18-inch diameter pipe.

3.Advantages

Horizontal directional drilling technology has proven to be the least impactful method of construction on the environment.

This technology also provides the most protective layer for the pipeline, with a corresponding reduction in maintenance costs, while not affecting river transport and shortening the construction period, proving to be the most efficient and least costly crossing method available.

4.Construction process and technology

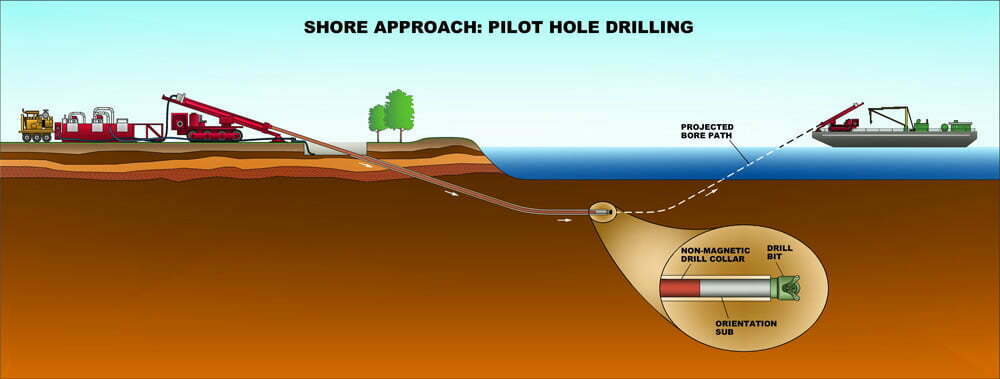

- Guided Holes

A pilot hole is a hole drilled horizontally at a predetermined angle and along a predetermined cross section, consisting of a straight diagonal section and a large radius arc.

While drilling the pilot hole, the contractor may choose and use a larger diameter drill pipe (i.e., flush pipe) to shield the pilot drill pipe.

The flush pipe can act like a conduit and can also facilitate tasks such as withdrawal of the pilot drill pipe and bit replacement.

Directional control of the pilot hole is accomplished by a controller (called a bent housing) located inside the drill pipe at the back end of the bit.

The drill pipe does not rotate during the drilling process, and if the curved housing is positioned to the right when the direction needs to be changed, the drilling route will proceed along a smooth curve to the right.

The drilling curve is measured by an electronic direction finder placed in the drill pipe at the back end of the drill bit and the measurement results are transmitted to the receiver on the ground. The measured data is compared with the designed data in order to determine the deviation of the actual position of the drill bit from the designed position and to control the deviation within the allowed range, and so on until the drill bit emerges at the predetermined position according to the predetermined guide hole curve.

- Pre-reaming

Once the pilot hole is completed, the hole is enlarged to the proper diameter to facilitate the installation of the finished pipe, a process known as pre-reaming (the number of reamings is determined by the final hole size).

For example, if a 36-inch pipe is to be installed, the hole must be expanded to 48 inches or larger. Typically, a reamer is attached to the drill pipe on the opposite side of the rig, and then the rig is rotated back and dragged into the pilot hole to enlarge the pilot hole, while a large amount of mud is pumped into the hole to ensure the integrity of the hole and not collapse, and to bring the cut rock chips back to the surface.

- Retracting pipeline

Once the pre-reaming is complete, the finished pipe can be dragged into the borehole.

The pipe pre-fabrication should be done on the opposite side of the drilling rig. One end of the reamer is connected to the drill pipe and the other end is connected to the finished pipe by a swivel joint.

The swivel joint prevents the finished pipe from rotating with the reamer to ensure a smooth drag into the borehole.

The dragging back is done by the drilling rig, which also requires a lot of mud, and the dragging back is done continuously until the reamer and the finished pipe break out from the side of the drilling rig.