First step:

Choose tracer wires.

There are several things you need to consider:

- Size of conductor. The common size of tracer wire is from 8 AWG to 18 AWG.

- The material of conductor. Copper clad steel wire or Pure Copper?

- The insulation of tracer wire: HDPE or PVC jacket?

- What is your application? Open-cut, Horizontal directional drilling, or Pipe bursting.

In conclusion, which we more recommend is Copper clad steel wire + HDPE jacket.

To sum up the advantage of copper clad steel wire.

- Same performance as pure copper.

- Excellent reliability

- Save material cost

- Strong Anti-corrosion

- Anti-theft

- Anti-aging Properties (HDPE jacket)

Second Step:

Choose Waterproof Connectors.

What kind of connectors we suggest you to buy:

- Impact resistant

- Waterproof and corrosion proof

- Saves time and money

- No pre-twisting required

- For use in lrrigation, Landscape Lighting

- Direct Burry ApplicationsPre-filled

- For Outdoor/Irrigation, Outdoor/Electrical wire splices usage

- For connections exposed to condensation, water, vapour or dust

Third Step:

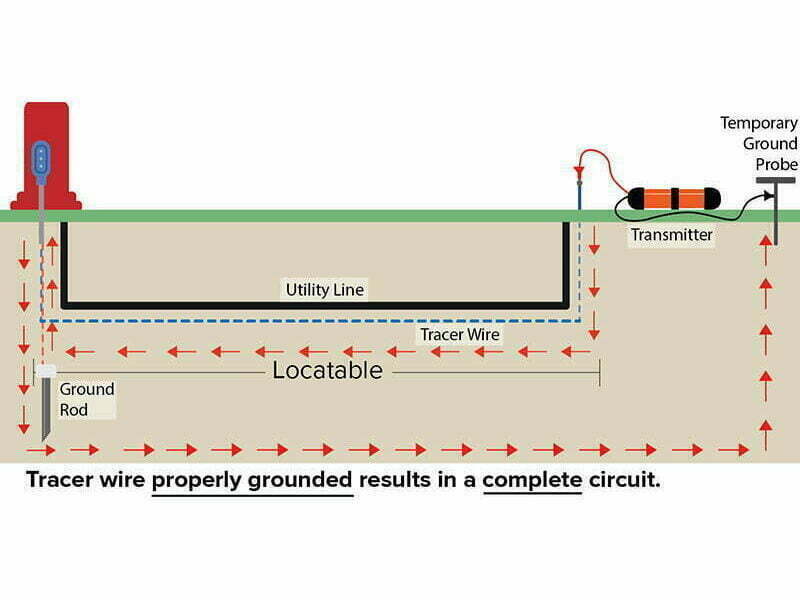

Ground Tracer Wires

In short, to make tracer wire is grounded properly.

Fourth Step:

Above all, access points can protect and provide direct connection to tracer wire systems.

Fifth Step:

Installed tracer wire properly. So that we can locate easily by multi-function locating equipment.

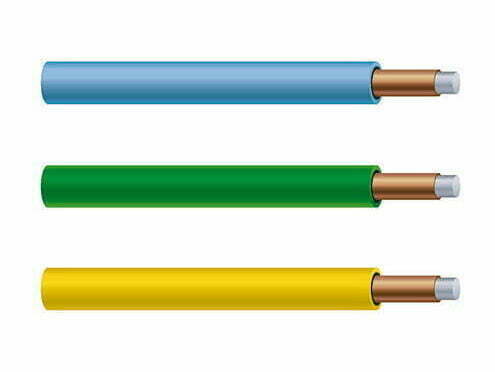

The Application of Tracer Wires

- YELLOW – Natural Gas Lines

- ORANGE – Fiber Optic, Signal and Communication Lines.

- BLUE – Potable Water Lines

- GREEN – Sewer and Drain Lines

- PURPLE – Reclaimed Water Lines

- RED – Electric Power Lines

- WHITE – Proposed Excavation