Abstract: The copper conductor tracer wire has limitations in terms of tensile strength and is prone to breakage during construction. We need to find a tracer wire with a good combination of signal and strength.

The following paper evaluates the resistance, tensile strength and signal properties of copper-clad steel tracer wire. We can find that copper-clad steel tracer wire can solve the problems of insufficient tensile strength of the copper conductor tracer wire, poor ageing resistance of the outer skin and non-waterproof joints.

It is worth promoting in the construction of PE pipelines.

PE pipe is a high molecular weight organic synthetic material. It has excellent anti-corrosion properties, is less expensive than copper pipes and is very convenient to construct. In recent years, we use this kind of wire in town gas projects.

However, as PE polymers are non-conductive and non-magnetic. It is not possible to detect the location of the pipe directly. So we need to bury a metal tracer wire with the PE pipe. Then we can determine the location and depth of the PE pipe by detecting the tracer wire.

Commonly used PE tracer using copper wire. But in the construction of gas pipelines, we often encounter poor construction site conditions. With the pipeline laying copper wire tracer line is prone to pull off the situation, this situation will have a certain impact on the subsequent tracer positioning of the pipeline.

In order to solve the problem of tracer wire pulling off during construction. We need to choose a tracer wire with better signal and strength for the project.

Problems with copper wire tracer wire

The outer surface insulation of copper wire tracer is PVC. It is easy to age after burial and cannot meet the requirements of the same life as PE pipe.

Its metal core is copper and has limitations in tensile strength. Take (2.5 m2) wire as an example. The tensile force is below 500N. We use it for excavation laying and non-excavation laying, the chance of breaking is higher.

Copper wire tracer wire connection, generally the two wire end cores wrapped around each other. After the use of electrical tape wrapped to cover the insulation layer location.

But, this treatment is not securely connected, the strength is not high, not effective waterproof insulation role.

Performance of copper-clad steel tracer wire

Copper-clad steel tracer wire structure

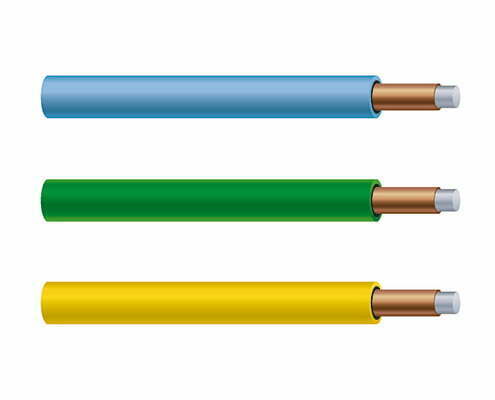

Common copper-clad tracer wires have three types:

1.single-wire 2.double-wire 3.multi-wire. With special connectors.

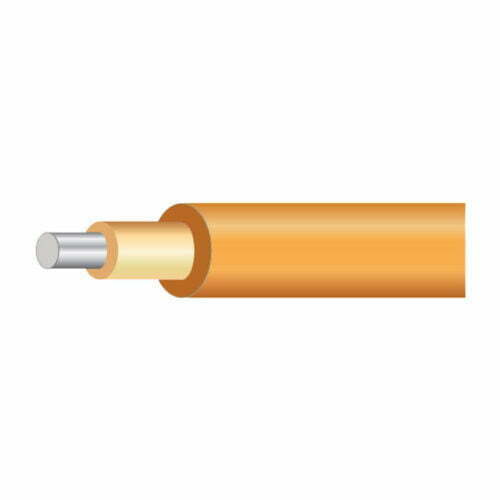

The outer layer is PE, which plays the role of insulation, anti-corrosion and waterproof. The inner layer is the steel core, which increases the strength of the wire body. And the middle layer is the copper layer, which enhances the electrical conductivity and improves the electrical signal.

Copper-clad steel tracer wire construction requirements

In the situation, we lay the tracer line in the PE pipe.

We need to place the tracer wire in a straight line directly above or on both sides of the pipe. And we should fix the tracer wire to the pipe with tape every 2 meters.

When the tracer line is applied to the non-excavated PE pipe, it should not have joints.

We should lay 2 tracer lines along both sides of the pipe. They should be taped every 2 meters with appropriate margins. The end of the entry point needs to be reinforced.

We need to set up enough signal source wells along the PE pipe for signal detection. Besides, we should insulate the end of the tracer line with waterproof.

Finally, after we complete the project, it is important to test the laid tracer line for detectability to ensure the signal effect of the tracer line.

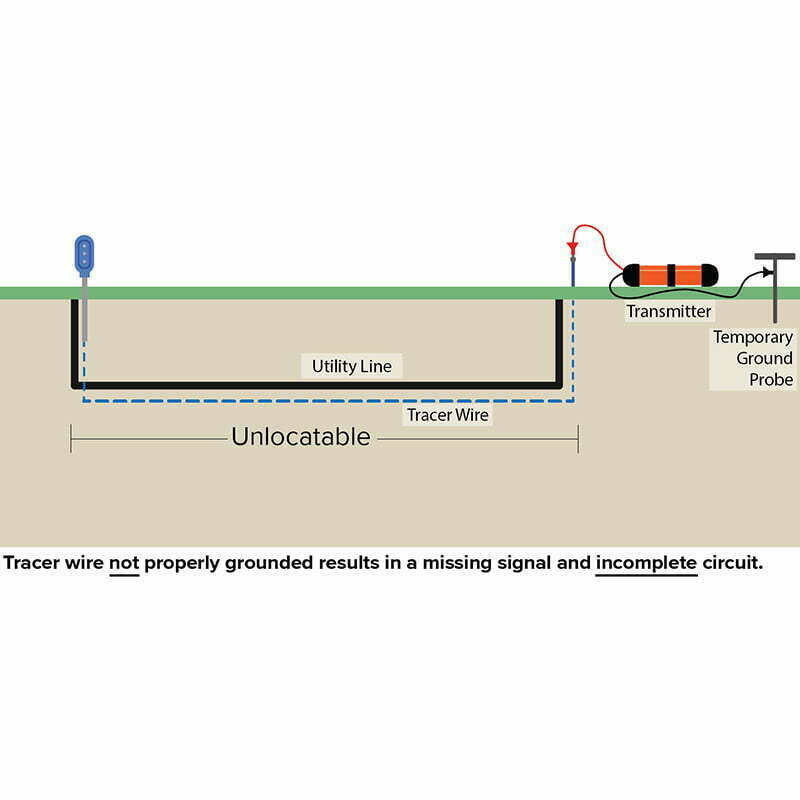

When we detect, we need to connect one end of the transmitter to the tracer conductor and the other end to ground. Most importantly, do not connect the transmitter to other pipelines to avoid signal interference. We can then use the receiver to detect the location and depth of burial of the pipeline along its general course.

Performance Test

In order to evaluate the feasibility of copper-clad steel tracer wires, we select three types of copper-clad steel tracer wires. They are A, B, and C, and we will test them together.

A: single wire structure, 5mm² core.

B: multi-wire construction, 7mm² core.

C: two-wire construction, single wire with 4.7 mm² core.

The test items include resistance, tracer wire tensile strength, connector convenience, connector water resistance, overall performance and signal strength.

Electrical resistance

In short, we tested the average value of the resistance of 2 tracer lines of 300 m long.

Tensile strength

To sum up, we tested 3 types of tracer wires for tensile properties to compare the advantages and disadvantages.

Connector convenience

Connecting 3 types of tracer wires with 2 connectors at the same time and comparing them according to the length of completion time.

Waterproofness of joints

Soak the location of the tracer wire connector in water and shake it continuously. 10 min later, remove the connector and compare the waterproof condition of the connector and the wiring.

Overall Performance

Overall Performance

For example, lay the 3 types of tracer lines together in the designated directional drilling project. Check the laying process for breakage, depth of tracer line outer skin scratches, etc.

Signal strength

Signal strength

For instance, lay the 3 tracer lines together in the designated directional drilling project. The tracer lines that have been laid are tested using a tracer instrument to compare the signal strength.

- In conclusion, please see Table 1 for tracer linear performance test results

| Performance Test | A | B | C |

|---|---|---|---|

| Electrical resistance (300m/Ω) | 21.2 | 28.4 | 24.6 |

| Tensile strength (N) | 4568 | 6587 | 4751 |

| Connector convenience (Total time spent) | 425 | 814 | 476 |

| Waterproofness of joints | No water inside the connector | As well | 100% waterproof |

| Overall Performance | Light scratches without breakage | Same as A | Same as B |

| Signal strength (%) | 97.5-99.9 | 96.8-99.9 | 96.3-99.9 |

Table 1 shows that copper-clad tracer wire types A, B and C3 all meet the signal strength required to detect pipelines. The tensile properties of the material are far superior to those of copper wire tracer wire. With the pipeline laying and non-excavation laying is not easy to break.

Single wire tracer A has a lower resistance than double wire tracer B and multi-wire tracer C. Short installation time for joints.

Economical

There are two types of PE pipeline tracer wire, the first for excavation and the second for non-excavation.

Copper clad tracer wire has more connector costs than copper wire tracer wire, but the price per metre is very much lower than copper wire.

Table 2 details the average material cost per metre of excavated and non-excavated tracer wire and the cost of wire tracer wire.

| Item | Copper Clad Steel Tracer Wire | Copper Tracer Wire |

| Excavation and laying / (CNY•m-1) | 1.8-2.0 | 1.9-2.2 |

| Non-excavation laying / (CNY•m-1) | 3.6-4.2 | 7.5-8.6 |

Concluding remarks

The copper-clad steel tracer wire as a whole meets the needs of detection and tracing.

In particular, the overall performance of the tensile strength, jointed waterproof wire is better than that of copper wire tracer wire.

The material cost of the excavated copper-clad steel tracer wire is slightly better than the wire tracer wire. While the price of the non-excavated tracer wire is much better than the copper wire tracer wire.