Underground pipelines are an important part of urban infrastructure and a lifeline for the survival and development of cities.

With the development of science and technology, the material of urban underground pipelines is also changing. In the past, a large number of metal pipelines were used, but now the application of plastic (polyethylene PE pipe, PVC pipe, etc.), ceramic, concrete and other non-metallic pipelines in various pipeline networks such as water supply, drainage, gas, heat, industry, oil and gas is becoming increasingly popular.

Because these non-metallic pipelines have the advantages of strong anti-pollution, light weight, low cost, not easy to corrode, easy to bury and maintenance, etc., they have been increasingly used to replace metal pipelines.

Underground metal pipeline detection technology has become mature, but the current detection of non-metallic pipelines is still a technical problem.

Because non-metallic pipelines do not conduct electricity nor magnetic conductivity. Basic insulation, the commonly used metal pipeline detector can not be detected. This brings great difficulties for determining the location and depth of underground non-metallic pipelines, avoiding damage caused by construction excavation, as well as the management and maintenance of pipeline network security.

How to quickly, accurately and easily detect non-metallic pipelines has become an urgent problem.

1 Detection method of underground non-metallic pipelines

1.1Ground Penetrating Radar

Ground Penetrating Radar (Ground Penetrating Radar), also known as geological radar, is the use of ultra-high-frequency electromagnetic wave detection of underground media distribution of a kind of physical detection instrument.

It emits high-frequency electromagnetic pulse waves, using the obvious physical differences between the underground medium and the pipeline (mainly the difference in electrical conductivity and dielectric constant), the pulse produces reflected and bypassed echoes at the interface, and based on the transmission time, amplitude and waveform information of the received echoes to determine the depth, location and estimate the diameter of the pipeline.

Ground-penetrating radar detection of non-metallic pipelines is fast, efficient, non-destructive and other characteristics, is the preferred tool for the detection of PVC, PE, concrete and other non-metallic pipelines.

However, it also has limitations, its detection depth and resolution are mutually constrained, the higher the frequency, the shallower the detection depth, the higher the resolution; conversely, the lower the frequency, the deeper the detection depth, the resolution also decreases accordingly.

Its detection effect and geological conditions are also closely related, when the media around the pipeline on the dissipation of electromagnetic waves is weak and the pipeline’s electromagnetic properties compared to its environment, the detection effect is good and relatively simple data processing.

On the contrary, it does not show a good performance, or even completely unsuitable. In addition, ground-penetrating radar echo signal contains a variety of noise, the echo signal filtering to remove noise, help improve detection accuracy, in the xiao da echo signal processing can apply neural networks, complex signal analysis techniques, wavelet transform and other methods to suppress noise, improve image quality.

1.2 Non-metallic pipeline detector

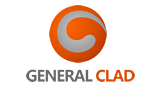

The detector is mainly composed of oscillator (transmitter), vibrator, receiver, probe, amplifier, headphones and other parts.

Generally applied to the internal fluid for the liquid state, with the pressure of non-metallic pipeline.

Its working principle (Figure 1) is the principle of sound waves, the use of sound in the pipe and its internal liquid propagation characteristics to detect the location of the pipe.

The basic method of use is: the oscillator (transmitter) emits a certain frequency of acoustic signals, the signal is transmitted to the pipeline through the vibrator connected to the pipeline, and along the buried pipeline to the far end, while the acoustic signal can also be transmitted to the ground.

The probe captures the acoustic signal on the ground and outputs it to the display meter and headphones after amplifying the signal through the receiver, so as to determine the location of the underground pipeline.

As the transmitter of the oscillator to be directly connected to the pipeline, so non-metallic

Metal pipeline detector must be used in places with pipeline facilities exposed points, such as water supply, drainage, gas pipelines, oscillators can be connected to water meters, fire hydrants, valves and other pipe fittings.

Non-metallic pipeline detector can only plane positioning of the pipeline, can not determine the burial depth; due to the attenuation characteristics of sound waves, the instrument is most suitable for the detection of small diameter pipelines; in addition, the detection of pipelines buried too deep is more difficult.

Currently the principle of the more advanced detector is the Japanese Fuji non-metallic pipeline detector, the latest model NPL-100 type.

Fuji on the previous model of the detector has made a number of technical improvements, so that the performance of the instrument has been greatly improved, such as equipped with a variety of fittings adapters, increased the frequency of automatic tuning function, increased the vibration of the sound waves sent, etc..

Numerous examples show that the use of acoustic principles developed by the underground non-metallic pipeline detector for water supply, fire and other pipeline detection have achieved good results.

1.3 Marking method

1.3.1 Marking and identification method.

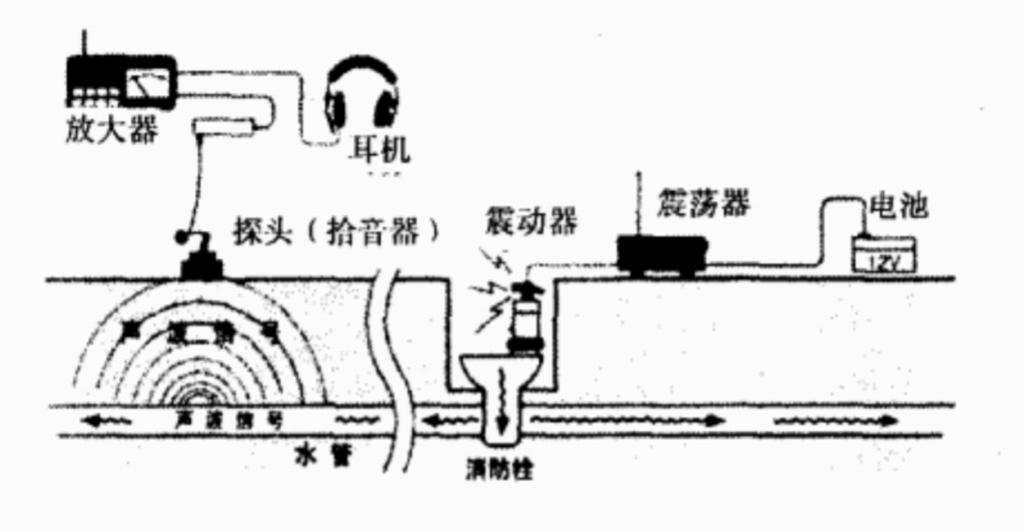

It is a kind of pipeline marking equipment, by the marker and marker detector two parts.

Its working principle (such as Figure 2) is: the marker detector to the ground to transmit a specific frequency of electromagnetic wave signal, when close to the marker pre-buried above the underground pipeline, the marker will produce the same frequency secondary magnetic field under the excitation of electromagnetic waves, the marker detector found and received the magnetic field, so as to determine the location of the marker.

While laying the underground pipeline, the marker is buried above the key parts of the pipeline, such as elbows, joints, branch points, maintenance points and parts that need to be found in the future, so that the marker can be found when the pipeline is found in the future, that is, the buried location of the pipeline is determined.

The service life of the marker is very long, and it will not be buried for a long time and rust or physical characteristics change.

The burial of the marker is very simple, it can be buried with the new pipeline, but also in the paved pipeline need to set the marker buried in the ground.

The use of marker finder underground pipeline is not easily disturbed by the external environment, can be buried in the complicated, crowded pipeline to identify the target pipeline, while the different frequency of the marker to identify the type and properties of the pipeline.

1.3.2 Tracer Wire marking method.

Detection of underground non-metallic pipelines is a world problem, the main reason is that non-metallic pipelines do not conduct electricity nor magnetic conductivity, basic insulation, can not use metal pipeline detectors to detect.

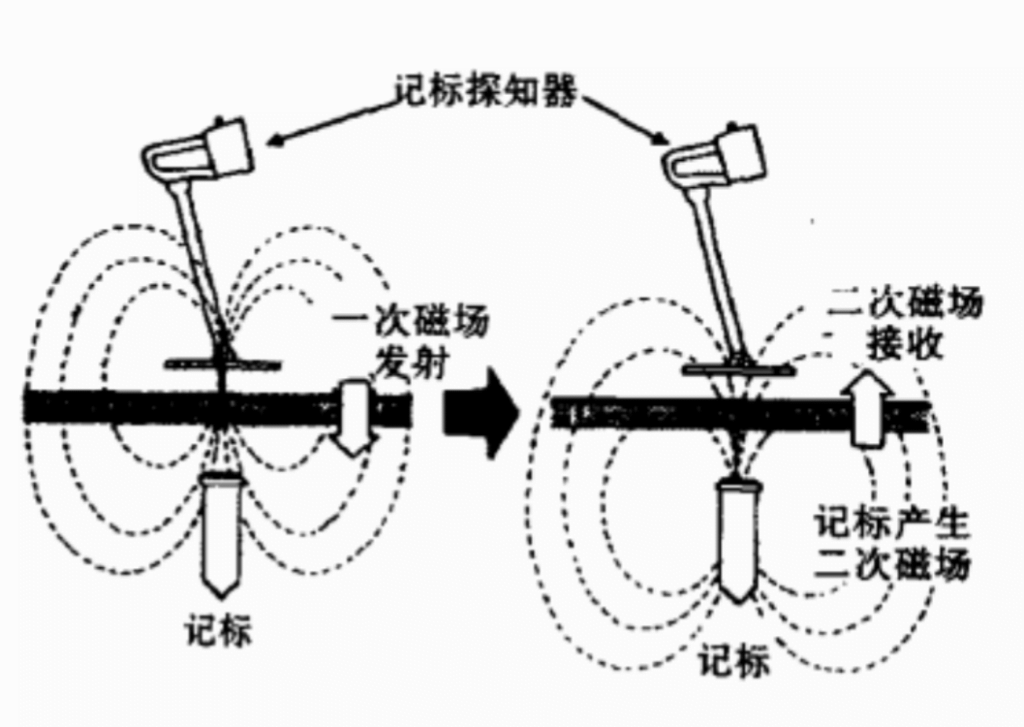

Tracer line is actually in the construction of non-metallic pipeline laying, and at the same time to complete the laying of a special wire.

Non-metallic pipeline with tracer wire, will make future investigation work easier, either with the active source method or passive source method, you can determine the spatial location of the tracer wire through the metal pipeline detector to detect the location of the center of the electromagnetic field generated by the tracer wire (Figure 3), so as to determine the location of the buried non-metallic pipeline purpose.

Tracer wire should not only have conductive properties, but also have a certain tensile strength and durability.

The current tracer wire core generally uses a single-stranded or multi-stranded copper core wire, wrapped with a plastic insulation layer outside, the insulation layer can also be replaced with conductive rubber, so that even if the core breaks will not affect the detection.

Tracer line should be buried close to the non-metallic pipeline in a straight line, and is located in the pipeline is good for the top.

In order to make the signal strong when detecting the tracer line, the construction of the tracer line end should minimize the grounding resistance.

Detection of the best use of direct signal to the tracer line method, so that less interference, strong signal, detection effect is more ideal.

1.4 other detection methods

For non-metallic pipelines with population can be used tracer electromagnetic method.

The principle is that the tracer probe or wire that can emit electromagnetic signals sent to the non-metallic pipeline, with the receiver to receive the probe or wire sent electromagnetic signals, so as to determine the location of the underground pipeline.

For power and telecommunications (plastic cladding) pipelines and reinforced concrete pipelines can be used electromagnetic induction method. For thermal pipelines can be used infrared radiation method.

2 Comparison of several non-metallic pipeline detection methods

| Detection method | Main application areas | Advantages | Disadvantages |

|---|---|---|---|

| Ground Penetrating Radar | Underground metallic or non-metallic pipelines | Wide range of applications and convenience | Often limited by the geological conditions around the pipeline. Interference times the appearance of many |

| Non-metallic pipeline detectors | Underground water supply, drainage, gas and other small diameter non-metallic pipelines | Good detection effect on water supply, drainage, gas and other pipelines | Applicable pipeline types are limited. Pipelines should have exposure points on the ground |

| Marking and marking method | Underground metallic or non-metallic pipelines | Simple burial, long service life | Can’t show the depth of the line, and the marker is easily lost after a long time. |

| Tracer wire marking method | Underground non-metallic pipelines | Simple and practical, easy to find | Not applicable to buried pipelines, which must be buried at the same time as the pipeline |

Concluding Remarks

Currently, non-metallic pipes are becoming increasingly popular in pipeline construction around the world, in view of the limitations of non-metallic pipeline detection.

In the future, on the one hand, to establish and improve the regulations and standards for the laying of underground pipelines, strict planning and approval procedures for various types of pipelines, strengthen the construction and completion management, and include in the pipeline acceptance standards to facilitate future pipeline detection. On the other hand, multiple detection equipment and multiple detection methods can be used for the paved pipelines.

In addition, focus on the research of better detection methods and the development of more efficient detection instruments. For the current common use of ground-penetrating radar, should mainly develop the ground-penetrating radar system with strong anti-interference ability, high quality of collected data, lightweight, fast processing speed, high resolution, convenient operation and relatively economical, they will also be the mainstream of commercial ground-penetrating radar development.