1. Undergrounding wire structure:

Undergrounding wire attached to plastic.

Since the microwave physical ground penetrating radar cannot detect plastic pipes.

Tracer wire will cause obstacles to future repairs and other constructions.

Therefore, when laying, attach a metal wire to the plastic pipe.

It can provide response signs for subsequent maintenance and construction.

2. Tracer wire test principle:

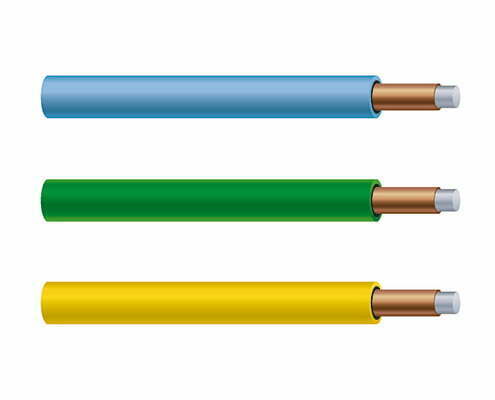

Copper clad steel is composed of steel core wire and copper layer. The outermost side is the PE anti-corrosion layer.

Copper plays a role in conducting weak electrical signals. The steel wire plays a supporting role.

Copper core wires generally have three structures:

Firstly, the innermost copper core wire

Secondly, tracer wire insulating wrapper of the middle layer

Thirdly, the outermost protective skin

The structure of copper clad aluminum wire:

1. Aluminum core wire

2. External copper layer

3. The outermost PE anti-corrosion layer.

Because the outermost anti-corrosion layer of the steel gas pipeline is a plastic layer or coating with insulating and anti-corrosion properties.

Likewise, it is similar to the plastic layer structure of copper-clad steel, copper-core wires, and copper-clad aluminum.

Therefore, we equate the two and use the PCM pipeline current attenuation rate method to detect the average insulation quality of the tracer line anticorrosive coating.

The detection principle is to apply a current signal of a certain frequency to the tracer line, and the current will gradually attenuate as it passes from the tracer line to a distance.

In conclusion, the attenuation is related to the insulation resistivity of the plastic layer of the tracer. The higher the average insulation resistivity of the plastic layer of the tracer, the slower the current decay, and vice versa.