Engineering construction and application of tracer line for PE polyethylene gas pipe network

First, gas pipe selection of tracer lines of different materials

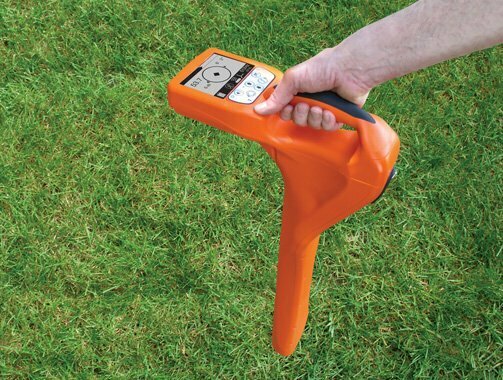

Theoretically speaking, when detecting the tracer line of the gas pipeline network.

As long as the current intensity can reach 300mA, we can get the detection structure.

In actual engineering testing, the tensile strength of tracer lines of different sections is different.

When the workers are backfilling the pipeline or the ground subsidence occurs.

They can easily break the tracer line and make it impossible to detect.

To this end, we can conclude from engineering practice that:

For copper core insulated wires with a cross-sectional area of 1.5mm² ~ 2.5mm². This application effect is better.

Workers are not easy to tear off during construction, and the signal quality is high.

Construction specifications and requirements for tracer lines of PE polyethylene gas pipe network

Tracer line is used as PE polyethylene gas pipe network.

To directly bury to detect buried depth and location information important medium.

Workers need to pay attention to the

Tracer wire is an important medium for PE polyethylene gas pipe network.

We can use this to detect buried depth and location information.

Workers need to pay attention to the following points during construction:

The first is when the workers make a back hook connection construction on the tracer line.

Do not use electrical tape or clear tape for wrapping.

First, this connection method is prone to connection problems in practice tests.

Secondly, it lacks waterproof insulation effect.

Finally, the signal strength is weak or disappears for future detection work.

The second is when workers are laying the branch pipes of the gas pipe network.

Do not directly subtract the end of the tracer line.

This action will cause the loop resistance between the pipeline and the ground to be too large.

And it has a serious impact on the detection signal strength.

The third is the phenomenon of incomplete information about the construction disclosure in the construction design.

for example:

- The description of the tracer line of the trenchless pipe section is not clear.

- The method of laying and connecting is not explained.

- The tracer line detection is prone to breakage.

Fourth, the construction technical specifications and supervision work are not in place.

Some construction units do not pay attention to the winding method and grounding requirements of the tracer wire. Wrap directly on the pipe. lead to bias in later detection.

Fifth, the reserved length of the tracer line is not enough.

It will have an impact on future detection and positioning.

Sixth, it is easy to cause problems at the direct three-way or four-way between the main pipeline and the branch pipeline:

First, the construction technology is not clear.

Second, the connection and grounding methods are difficult to pinpoint.

Third, the construction processing is free to connect.

Fourth, the detection result is invalid.